Artwork orientation & Data setup

Printing Basics

Ink set-off

Frequently, people associate the use of super rich, dark colours with getting the richest, deepest colour. In printing, we want to avoid using heavy, saturated colours because of the problems it may cause during production.

If the ink is unable to dry properly (because of the heavy ink coverage on the surface) when the sheets are stacked on top of each other,some of the wet ink may end up transferring onto the edges of the sheet behind it. During the trimming process, the pressure forced onto the paper by the trimming machine can cause some of this ‘ink rubbing’ to happen.

We take great caution and use preventive measures like extending the period dry-time required, but there are times when we cannot prevent it absolutely because of the paper type, weather conditions or design type.

When designs have dark colour on the edges

Front

Paper prone to ink rubbing

Wood Free, Matt Art

Back

How to reduce the possibility

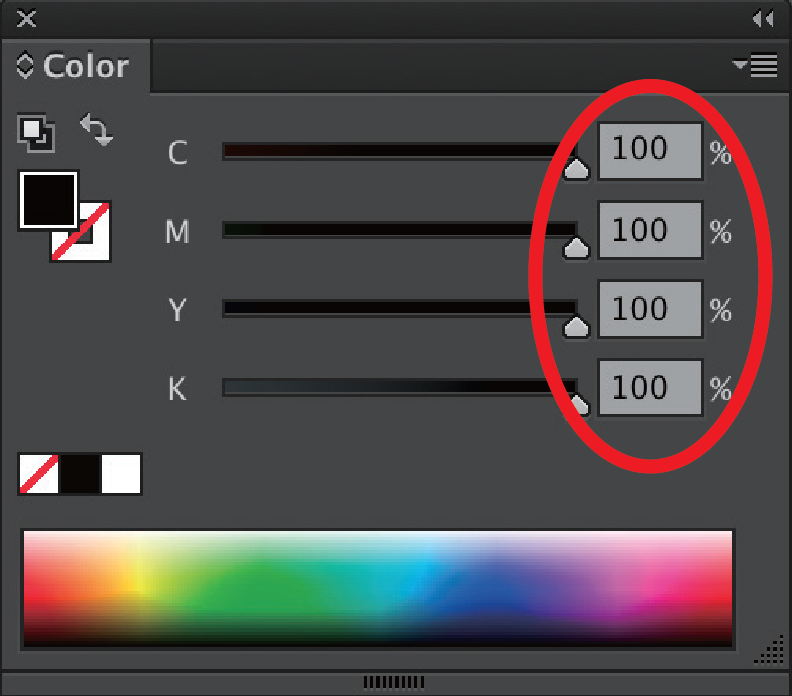

- Keep the CMYK total under 220%

- Avoid dark front colour / white back designs

- Avoid papers that are prone to ink rubbing

- Adjust your layout to a simpler design

Ink may transfer onto the touching sheets!

Avoid heavy ink coverage

Designs with CMYK values exceeding 220% may causing printed sheets to stick together.

Please ensure the CMYK total ink density does not exceed this limit when preparing your data.

Will result in ink rubbing and/or

the paper sticking together

info@metroprint.ph

info@metroprint.ph

0945 826 3908

0945 826 3908

0945 826 3908

0945 826 3908